Laurian gave Buckeye Shapeform a sketch, and the company’s engineers replied with detailed plans for how the box could be built within budget. “They got the job.”This is just placeholder text. Don’t be alarmed, this is just here to fill up space since your finalized copy isn’t ready yet. Once we have your content finalized, we’ll replace this placeholder text with your real content.

We Fabricate Metal, Plastic Enclosures, Precisely to Your Design Requirements. —Made in the USA.

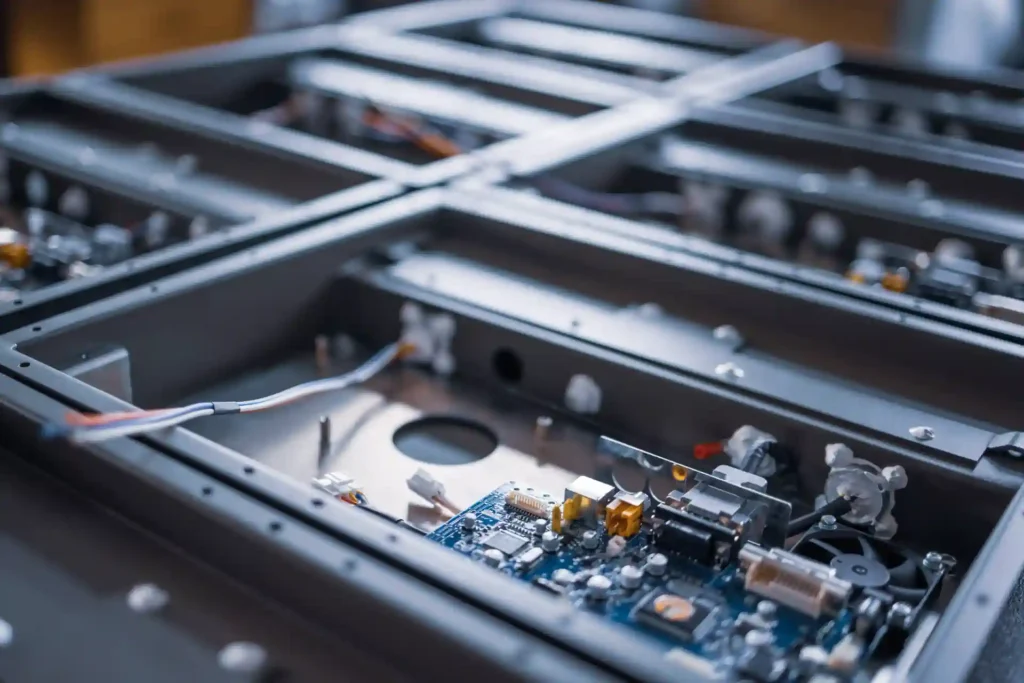

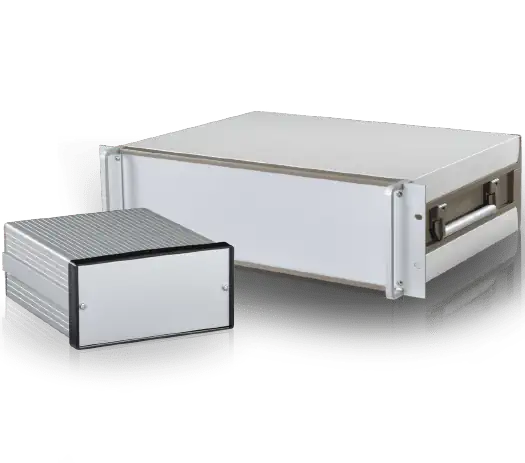

Electronic Enclosures

Choose from and established line of enclosures featuring rack mounts, desktop, panel mounts & more.

See Our Enclosures

Metal Cans

Our Seamless Metal Tins are versatile and durable for a wide range of products.

See Our Containers

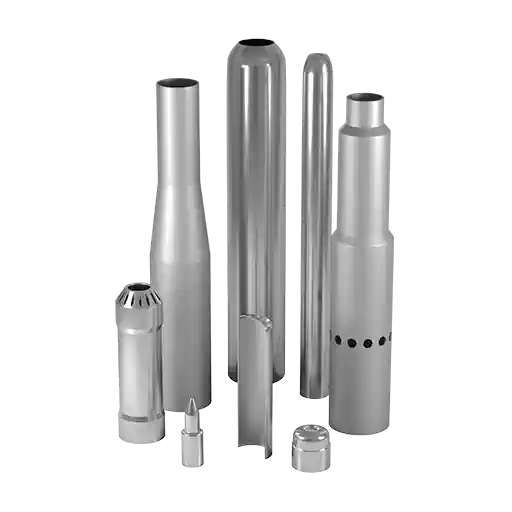

Deep Draw

We are the industry experts in Deep Draw Metal Fabrication resulting in a 20:1 Ratio.

See Our Deep Draw Tech

Discover Our Vertically Integrated Process

Our Process = Higher Quality, Timely Production and Cost Savings.

Vertically

Integrated

Production

Are You Doing It Yourself? Ask Our Engineers!

Get Expert HelpWe Expertly Craft These Materials and More

Our advanced expertise allows us to work seamlessly with both ferrous and non-ferrous metals. Explore our collection of materials—stainless steel, cold-rolled steel, and aluminum—or let us know your preferences for a custom design that fits your project perfectly.

Stainless Steel

Carbon Steel

Aluminum

Plastic

Proudly Providing Service to the Best Across These Industries

Vertically Integrated Production Under One Roof

Our Manufacturing Process

We Built Our Reputation with Customization

Metal Laser Cutting

Essential Metal Working

Metal laser cutting is the first step in our process to create a custom enclosure. We use laser cutting to create highly precise cutouts not only in enclosures, but various sheet metal applications.

Metal Forming

Exact Specifications

Forming involves taking the previously cut sheet of metal and forming it into its intended geometric shape, whether that’s cylindrical, rectangular, square, etc.

Machining & Milling

High Tolerance

One of the many custom add value services we offer. We can machine both flat and cylindrical shapes and meet specific tolerances with our advanced machining technology.

Welding

Perfect Connections

Our welders perform three different types of welds—MIG, TIG and spot welds—as needed to produce quality finished products.

Metal Finishing

Protection and Luxurious

Unlike many metal manufacturers, Buckeye Shapeform offers metal finishing capabilities in-house to keep your project under budget and on time.

yrs

Tradition

Craftsmanship Pride

Customizable Flexible | Precise

FAQ’s: Find Answers to Your Questions

If you still need an answer to a question that is not covered here, please reach out to us!

Contact usAre your tin containers manufactured in the United States?

Yes, all of our tin containers are manufactured in the United States. Contact us to learn more or call 800-728-0776

Can seamless tins be custom embossed?

Yes; however, a tooling charge is required for custom embossing. Contact us to learn more or call 800-728-0776

Are your seamless tin containers oil-free?

Yes.

Are your seamless tin containers FDA-approved?

At this time are not FDA approved.

What is your return policy for tin containers?

A Purchaser shall have ten (10) days following receipt of shipment of the goods in which to inspect and notify Company that the goods were not as warranted. Purchaser shall grant Company access to the goods at all reasonable times in order for Company to determine any defect in the goods. In the event Company determines in its sole discretion that the goods were not as warranted on the date of shipment, Company will replace the defective goods. Purchaser shall assume all responsibility and expense for removal, and freight in connection with the foregoing remedy. Company and its suppliers shall have no responsibility if the goods have been improperly stored or handled. Please see out standard terms and conditions of sales for complete explanation. Contact us to learn more or call 800-728-0776

How long will I have to wait for my seamless tin containers?

We ship in-stock tin containers within three days. Contact us to learn more or call 800-728-0776

What type of material does Buckeye Shapeform use to manufacture seamless tins?

Tinplated steel Contact us to learn more or call 800-728-0776

Are You Ready to get Started with Your Next Project?

We are excited to learn about your project and share how we can help!