Today, it’s more affordable and more convenient than ever for an OEM or product designer to acquire a custom enclosure that’s perfectly configured to a specific product or application design.

Enclosure manufacturers like Buckeye Shapeform now offer detailed enclosure design and customization services—offering OEMs and designers the flexibility and freedom to build their products without being forced to fit inside a standard enclosure footprint. Partnering with an enclosure manufacturer that has the latest enclosure customization technology makes designing a custom case incredibly simple.

Sometimes starting with a standard enclosure and modifying it to fit a product design will work, other times, it’s best to design and build a completely custom solution. Look for an enclosure manufacturer that can provide these eight customization services in-house to save you time and money:

Special Sizes

Modify the height, width and/or depth of the enclosure. If using an extruded case, extrusions can sometimes be cut to specific depths to better accommodate the product design.

Self-clinching inserts

Inserts such as studs, standoffs, blind studs, captive nuts, spring latches, rivets and right angle standoffs are available in a variety of sizes and can often be added to a case in order to mount electronics or hardware.

Punching and holes

OEMs may want holes punched into their enclosure in order to mount internal components or allow for venting. Punches and holes can come in a variety of sizes, configurations and shapes, ranging from square, to round, to trapezoid.

Machining

If an enclosure manufacturer has dedicated CNC milling equipment, it can create virtually any shape a customer requires. A machining process can be used for holes, vents, corner radius, cutouts, counter boring and other customized processes to extruded aluminum enclosures.

Finishing

Enclosures are often finished with an undercoat and topcoat to provide a durable and attractive finish that protects a product and helps it function at its best. An OEM can choose from a variety of finishing options, depending on the final use of the product.

Shielding

Shielding protects products by limiting interference into or out of an enclosure. It’s particularly important for products that include highly sensitive components inside the enclosure or for enclosures that will be placed near other sensitive equipment or components.

Masking

For plated or painted enclosure components, a masking process creates a raw contact surface, which is essential for improving the effectiveness of the shielding process.

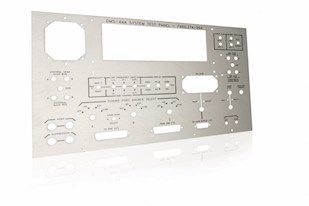

Graphics and silk-screening

Customize a product by adding a company or product name, logo or other artwork on an enclosure. Buckeye Shapeform uses the industry’s latest technology in-house to produce any type of enclosure a customer requires. This allows OEMs and product designers to get everything they need—all from a single source. When working with Buckeye Shapeform, an OEM ultimately lowers costs, simplifies billing and quickens product speed to market.

Contact Buckeye Shapeform today to learn more about its custom enclosure capabilities.