Buckeye Shapeform are Experts in Deep Draw Metal Fabrication —Made in the USA

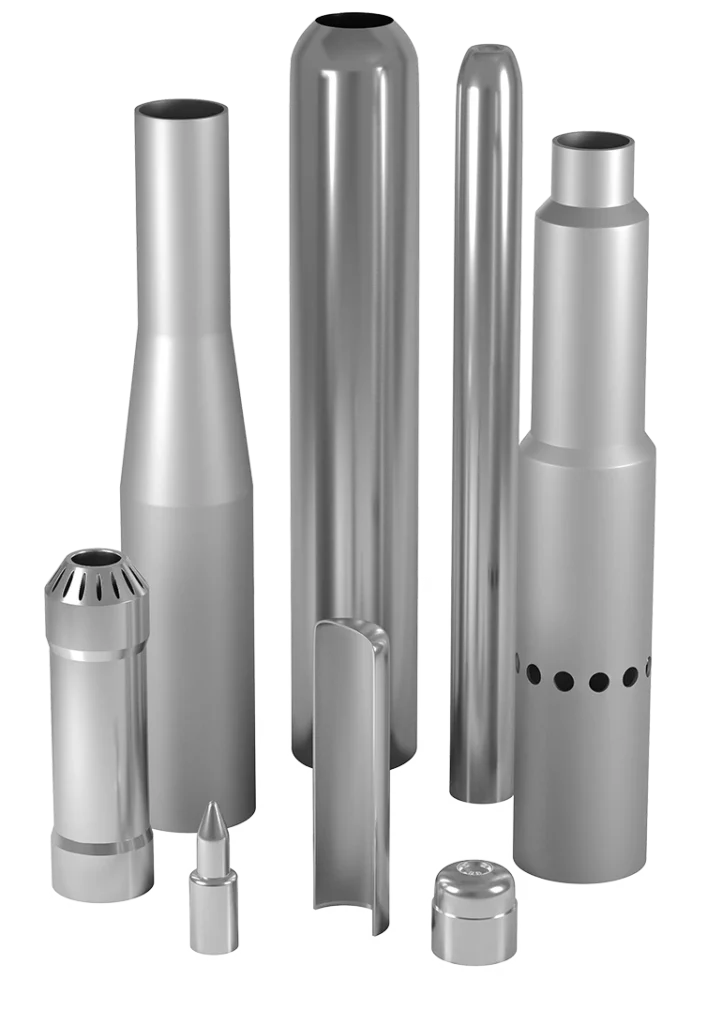

Deep Draw Technology for Metal Manufacturing

Buckeye Shapeform - a leading manufacturer specializing in Deep Draw Technology and high precision in-house manufacturing. With our extensive experience and commitment to quality, we take pride in delivering top-notch solutions made in the USA.

- Highly Calibrated

- 3D Scanned for Tolerances

- Minimal Weight + Uncompromised Strength

Deep Draw Technology | Precise | Reliable | Up to 20:1 Form Ratio

Leading the Way in Metal Forming At Buckeye Shapeform

We are recognized as industry leaders in Deep Draw Technology. This specialized metal forming process offers numerous advantages, providing a cost-friendly and reliable alternative to other techniques such as impact and spinning. With our deep draw expertise, businesses across various industries can experience higher output with lower costs, revolutionizing their metal forming processes.

Buckeye Shapeform's Deep Draw Technology Provides:

Geometrical Positional

0.003/inchTolerance

Surface Roughness

0Microinchesor Less

- Zero Defects

Advanced 3D Scanning

- Multi Thickness

Capability Increases Strength

Benefits of Deep Draw Technology:

Improved Accuracy:

Our deep draw process ensures highly calibrated products, meeting tight tolerances in the thousandths, delivering superior accuracy.

Sealable Finishes:

Eliminate the need for secondary operations with our sealable finishes, achieving a surface roughness of 63 micro inches or less. This enables direct application sealing of gaskets during final assembly.

Flexible Hardness:

In certain cases, aluminum proves to be a better choice than steel. Using deep draw techniques, we create strong and ductile products with an aluminum uniform grain structure, effectively reducing vibrations. This feature is especially crucial for electronics and technology-based hardware.

More from Less:

Aluminum offers three times the effective product as compared to steel. With deep draw technology, minimal weight is achieved without compromising strength, making it ideal for mission-critical parts that require both durability and lightweight design.

High Precision In-House Manufacturing:

Buckeye Shapeform takes pride in our state-of-the-art, in-house manufacturing facilities, ensuring unparalleled precision and quality control. Our team utilizes modern fabrication techniques and advanced equipment to meet the most rigorous manufacturing challenges. With our expertise, we consistently deliver perfect products, meeting the exact specifications of our customers.

Made in the USA:

We are dedicated to supporting American manufacturing. All our products are proudly made in the USA, adhering to the highest industry standards. By choosing Buckeye Shapeform, you not only receive superior products but also contribute to the growth of the local economy.

Partner with Buckeye Shapeform Today:

Experience the exceptional capabilities of Buckeye Shapeform’s Deep Draw Technology and high precision in-house manufacturing. Our team is ready to assist you in achieving your goals with our expertise and commitment to excellence. Contact us today for a personalized quote and discover why we are the preferred choice for businesses seeking reliable metal forming solutions.

Main Features

This is just placeholder text. Don’t be alarmed, this is just here to fill up space since your finalized copy isn’t ready yet. Once we have your content finalized, we’ll replace this placeholder text with your real content.

This is just placeholder text. Don’t be alarmed, this is just here to fill up space since your finalized copy isn’t ready yet. Once we have your content finalized, we’ll replace this placeholder text with your real content.

This is just placeholder text. Don’t be alarmed, this is just here to fill up space since your finalized copy isn’t ready yet. Once we have your content finalized, we’ll replace this placeholder text with your real content.

This is just placeholder text. Don’t be alarmed, this is just here to fill up space since your finalized copy isn’t ready yet. Once we have your content finalized, we’ll replace this placeholder text with your real content.

Discover Our Vertically Integrated Process

Our Process = Higher Quality, Timely Production and Cost Savings.

Vertically

Integrated

Production

yrs

Tradition

Craftsmanship Pride

Customizable Flexible | Precise

FAQ’s: Find Answers to Your Questions

If you still need an answer to a question that is not covered here, please reach out to us!

Contact usAre your tin containers manufactured in the United States?

Yes, all of our tin containers are manufactured in the United States. Contact us to learn more or call 800-728-0776

Can seamless tins be custom embossed?

Yes; however, a tooling charge is required for custom embossing. Contact us to learn more or call 800-728-0776

Are your seamless tin containers oil-free?

Yes.

Are your seamless tin containers FDA-approved?

At this time are not FDA approved.

What is your return policy for tin containers?

A Purchaser shall have ten (10) days following receipt of shipment of the goods in which to inspect and notify Company that the goods were not as warranted. Purchaser shall grant Company access to the goods at all reasonable times in order for Company to determine any defect in the goods. In the event Company determines in its sole discretion that the goods were not as warranted on the date of shipment, Company will replace the defective goods. Purchaser shall assume all responsibility and expense for removal, and freight in connection with the foregoing remedy. Company and its suppliers shall have no responsibility if the goods have been improperly stored or handled. Please see out standard terms and conditions of sales for complete explanation. Contact us to learn more or call 800-728-0776

How long will I have to wait for my seamless tin containers?

We ship in-stock tin containers within three days. Contact us to learn more or call 800-728-0776

What type of material does Buckeye Shapeform use to manufacture seamless tins?

Tinplated steel Contact us to learn more or call 800-728-0776

Can't find what you need?

We Can Help.

just let us know what you need.