Metal Laser Cutting for Custom Enclosures

Metal laser cutting is the first step in our process to create a custom enclosure. We use laser cutting to create highly precise cutouts in enclosures for electronics and other technology-based hardware, medical devices and more.

Any industry can benefit from higher output and lower costs when it comes to custom metal work for a product, and it starts with more efficient metal laser cutting. Learn more about the metal manufacturing process at Buckeye Shapeform.

Our Custom Metal Manufacturing Process

You can choose from our standard stock of enclosures and containers, or our engineering team can partner with you to create a custom design via our comprehensive metal manufacturing process.

Metal Laser Cutting

Machining & Milling

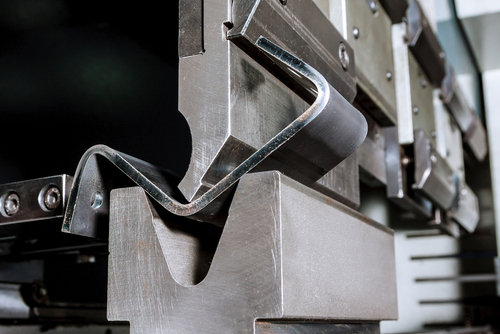

Metal Forming

Welding

Metal Finishing

Advantages of Laser Cutting

- Flexible, with endless design capabilities

- Accurate, with precise cutting quality

- Efficient, due to repeatable processes

- Cost effective to help you stay within your budget

- Automated for time-sensitive projects and large runs

- Versatile, as we are able to cut different gauges of sheet metal

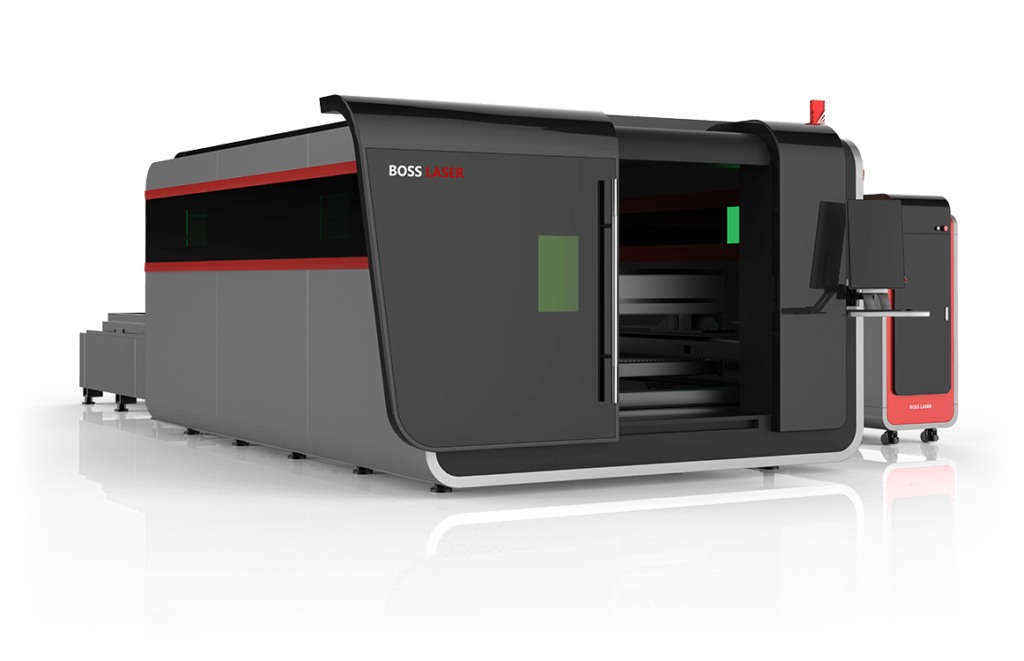

Laser Cutting Machines

We are specialists in meeting your custom requirements, and both our team and our equipment reflect the highest quality manufacturing standards in the marketplace.

BOSS FC-6012 EXT Fiber Laser Cutter

- Yaskawa’s Sigma7TM servo series of motors and drivers was designed to maximize responsiveness in applications where precise load matching is critical.

- Atlanta Helical Gear Racks From Atlanta Drive Systems™ offers high-precision parallelism that allows for drives with extremely low backlash without the need for preloading.

- Manufactured to aerospace standards to 6061 T6 – hardened aluminum alloy. T6 temper 6061 aluminum is treated to yield maximum strength.

- The Swiss-engineered fiber laser cutting head that eliminates collimation lens contamination, ensuring increased focus and accuracy.

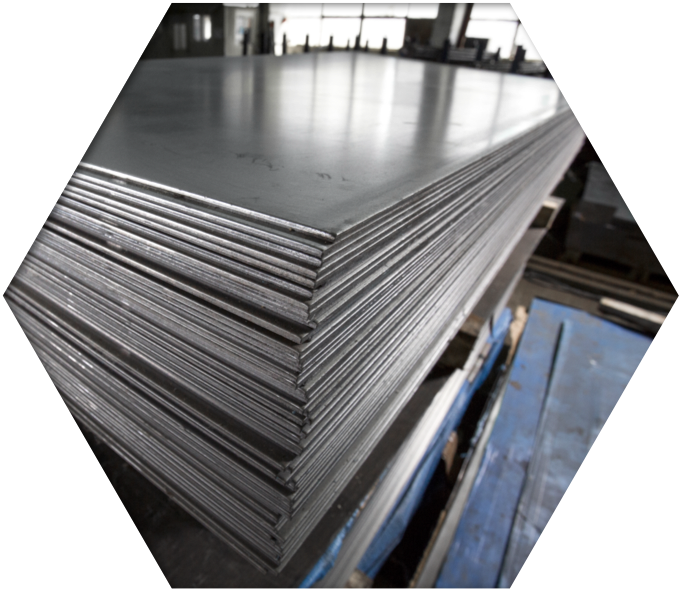

Materials We Work With

Our advanced laser cutter allows us to cut both ferrous and non-ferrous metals, including:

Stainless Steel up to .393in. [10mm]

Carbon Steel up to .708in. [18mm]

Aluminum up to .236in. [6mm]

We also have brass, copper, titanium, gold, and silver cutting capabilities.