Metal Machining & Milling

Milling is the process of machining a sheet of metal using rotary cutters to remove material. It’s one of the most commonly used processes to machine custom metal parts to tight tolerances.

The difference at Buckeye Shapeform? Milling is just one of the many steps in our metal enclosure fabrication process that we retain in-house in order to offer our customers lower costs and quicker turnaround times. Operating the most recent technology allows us to make more precise cuts and meet tighter tolerances than our competitors, resulting in a higher-quality end product.

Our Custom Metal Manufacturing Process

You can choose from our standard stock of enclosures and containers, or our engineering team can partner with you to create a custom design via our comprehensive metal manufacturing process.

Metal Laser Cutting

Machining & Milling

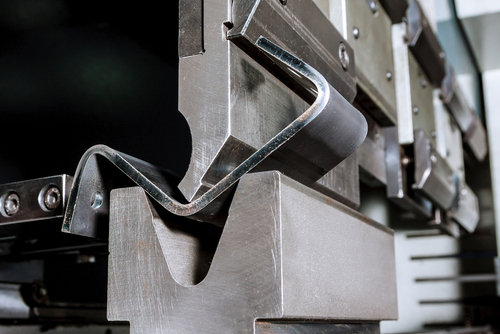

Metal Forming

Welding

Metal Finishing

Advantages of In-House Machining & Milling

- Flexible, with endless design capabilities

- Accurate, with precise cutting quality

- Efficient, due to repeatable processes

- Cost-effective to help you stay within your budget

- Automated for time-sensitive projects and large runs

Machining & Milling Equipment

We are specialists in meeting your custom machining and milling requirements. Both our team and our equipment reflect the highest quality manufacturing standards in the marketplace.

Utilizing various three- and four-axis machining centers, as well as mill-turn machining centers, we are capable of supporting low, medium and large production quantities. Our equipment services a broad range of materials including aluminum, cold rolled steel, stainless steel, brass and copper. We also machine plastics — ABS, acrylic, lexan and polycarbonate, to name a few.

Deep Draw for Machining Complex Shapes

Materials We Work With

Our advanced machining equipment allows us to work with both ferrous and non-ferrous metals, including:

- Stainless Steel up to .393in. [10mm]

- Carbon Steel up to .708in. [18mm]

- Aluminum up to .236in. [6mm]

We also have brass, copper, titanium, gold, and silver cutting capabilities.