Metal Stamping for Custom Enclosures

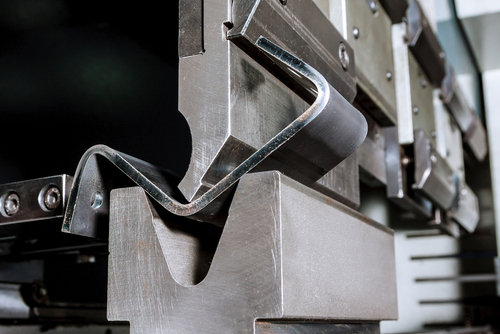

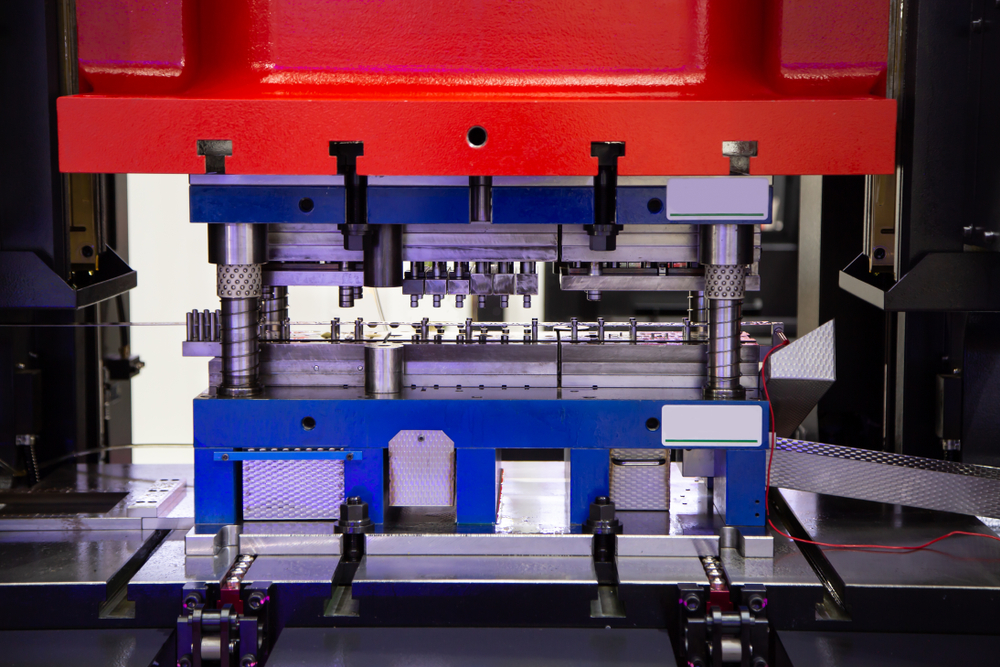

Metal stamping is all about transformation. This cold-forming process uses dies and stamping presses to transform sheet metal into different shapes. This is an excellent technique for repeatable, high-volume production runs. When it comes to creating your customizable enclosures, this invaluable technique will set your project up for success.

At Buckeye Shapeform, we create unique metal enclosures that can be used for a wide variety of applications. Just like we create enclosures and stamped products for the aerospace industry, we use these same high standards for your projects as well. No matter what you need to have stamped, our careful attention to detail and high quality products will set you up for success.

Our Custom Metal Manufacturing Process

Metal Laser Cutting

Machining & Milling

Metal Forming

Welding

Metal Finishing

You can choose from our standard stock of enclosures and containers, or our engineering team can partner with you to create a custom design via our comprehensive metal manufacturing process.

Where Metal Stamping Fits In

Advantages of Metal Stamping

- High volume makes it faster and cheaper

- Customized to stamp metal design that fits your project

- Efficient for a faster timeline

- Low price point keeps your project on budget

- Recyclable so you don’t waste the leftover materials

Metal Stamping Equipment

Materials We Work With

- Tin-plated steel

- Aluminum

- Stainless steel

- Coal rolled steel (CRS)